Table Of Content

With the mechanical advantage working in the opposite direction moving a short distance with more force results in less force in the output but moving a larger distance. Rotational inertia is the resistance an object has to changing its state of rotation. For an object that is not rotating we commonly talk about its inertia or its mass; the more mass the object has, the more resistance the object will have to any change in it's state of motion. With rotational inertia we still talk about an objects mass but we include the location of it's mass with respect to the point of rotation. The greater the distance between the average mass of a rotating object and its point of rotation means the greater the rotational inertia of the object (large wheels have more rotational inertia).

Step 1: Materials you’ll need

Needless to say, most of the cars he saw there were not perfect, but these kids came up with ingenious solutions to this seemingly simple problem. Remove the metal catch and hook from the mousetrap and discard. Glue the pre-drilled balsa wood to the mousetrap, lining up one side with the mousetrap and having the other side extend past the mousetrap body.

Step 7: Finishing Touches

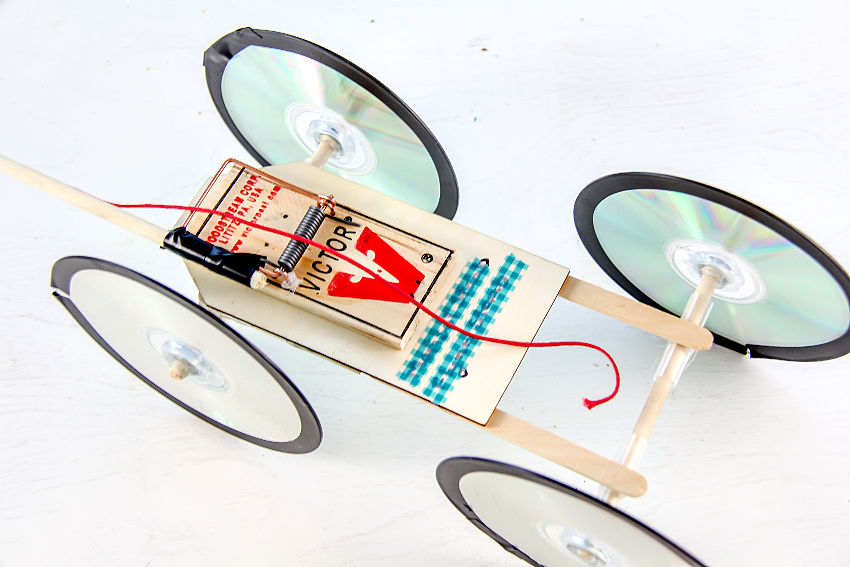

One of the things that makes mousetrap-powered cars so fascinating is their simplicity. Even though they work using principles of physics, you certainly don't need to be a physicist to build and enjoy them. Making a mousetrap car go as far as possible relies on a few guiding design principles. You’ll want to design your car to have a light body, have large rear wheels, and you’ll want to position the mousetrap as close to the front of the car as possible. This helps prevents the drive wheels from slipping out of the gap over time. Step 6Now, along with the short sides, screw the 4 eyelets in the mouse trap.

Is friction beneficial to a mousetrap car?

A mousetrap car project is an interesting, yet sort of a harrowing project. It is often used in physics classes to help students understand concepts in physics and faculties related to mechanics. The following passages elucidate step-by-step instructions to make one.

The torque (amount of twisting force) decreases proportionally as measured farther out from the spring along the lever arm. Almost everything I know about mousetrap cars I can credit to reading this book from Doc Fizzix’s. I highly recommend purchasing this book and also a mousetrap car kit from Doc Fizzix’s. After building a good kit car, designing your own will be much easier. Next we can cut our dowel to length and attach to our mousetrap.

Power Output

Wrap a small rubber band around the axle on either side of each wheel so the wheels can’t fall off. Make sure that the axles are straight and that there is room for them to spin in the eye hooks. Screw the eye hooks onto the bottom of the cardboard chassis, one in each corner. Use a ruler to make sure that the eye hooks are aligned with each other. Give your wheels some traction by stretching large rubber bands around each wheel. For the small wheels, you could also try using a section of a balloon.

Step 2: Introduce Finite Element Modeling in Fusion360 (optional)

The result is one of the most significant and unforgettable structures in Los Angeles. For this reason the California studios have become the place where American cars are designed for European and Japanese companies. This trend toward regional designs has been going on for several years but it is now making itself felt in the marketplace. Mr. Matano points out that it's important to have a common data set from beginning to end of a project. It helps if a designer starts using a computer-aided design (CAD) program at an early stage as it brings the designers into the loop with engineers.

Step 6: Extend the Mousetrap Arm

I have been thinking more about how math could be used to predict an outcome. It is also interesting to see how the force decreases as the spring unwinds. Put a generous amount of hot glue into the gap between the cubes. Wait a moment for the glue to begin to cool, otherwise the heat may melt or deform the straw pieces, which will generate lots of unnecessary friction. Once the glue is tacky, set the small straw pieces of the drive wheels into the gap (picture 1).

Many employers and even some schools want to see a design portfolio of applicants, and this website can serve as a piece of your portfolio that you will be building as you continue your education. The website should reflect the pride you take in your work, and one that you would be happy to share with a potential employer as an exemplary example of the engineering work that you have done. Put a couple rubber bands around the back wheels to add traction to the car. We are now going to modify the mousetrap so that it works well to power our car. Mousetraps are very versatile, so you’ll be able to think of lots of things to do with them once you’ve used them for your car. Especially if you’re interested in making something more complex than a simple car, you can start by modifying your trap and seeing what other devices you can make it power.

Hands-on Learning: Of rockets and mousetraps - Lewiston Sun Journal

Hands-on Learning: Of rockets and mousetraps.

Posted: Mon, 09 May 2022 07:00:00 GMT [source]

Tie a string very tightly to the snapper arm on the mouse trap. The string should be long enough to just reach to the back axle. Cut the wooden dowel so you have two pieces that are both about two inches longer than the width of the chassis. Cut a piece of strong cardboard so that it is slightly larger (about 1/2″) than the mousetrap on every side. Having a light bodied mouse trap car allows for less work to have to be done by the mousetrap getting the car going.

Attach a 4” zip tie to the center of the axle exposed by the notch in the cardboard, and cut it short, about ¼ inch. The goal is to design a mousetrap car to travel the farthest distance. See the rules above for the complete list of the design rules. This is a chance for you and a your group to utilize CAD to assist in the design process, and rapid manufacturing of a mousetrap car.

After some thought on how to incorporate the 3D printers I put a new twist on an old project. In this instructable I will be covering the steps on how to design and build a 3D printed mousetrap car. The first mousetrap cars were built in the 1960s, but there isn’t much information about who made them or what they looked like. The modern design was popularized by Loren Sach’s book on making a variety of toys, including one for mousetrap cars. They should be made out of wood dowels that are slightly smaller than the inside diameter of your mousetraps.

The string is tied to the tip of an arm that is attached to a drive axle by a string. As the string is wound around the axle, the lever arm on the mousetrap is pulled and the spring is wound, thus storing energy in the spring. When the drive wheels are released, the string is unwound from the axle which causes the mousetrap car to move. Friction is the force that acts against the motion of all moving objects. We cannot eliminate friction totally but we can try to reduce it as much as possible. As a general rule of thumb, the more moving parts a device has the greater the force of friction acting against the system.

Rober visits his friend, the world record holder for mouse trap car distance, to find out how he does it. The cars physics are all about mechanical advantage, the trade off between how long it takes to do something and how little force is required to do it. In the case of mouse trap cars, that means that the slower the car goes, the farther it can travel.

HYTREK: Neb. students learn how to build a better mousetrap car - Sioux City Journal

HYTREK: Neb. students learn how to build a better mousetrap car.

Posted: Tue, 23 Dec 2014 08:00:00 GMT [source]

Mr. Matano says this has helped speed up the whole process in developing a new car. This sentiment is echoed by Mark Stehrenberger, a teacher and designer in his own right, at Art Center College of Design in Pasadena. Mr. Mays already had a legacy because he can take much of the credit for VW's New Beetle, which is set to be one of the most talked about production car designs in many years. Although some would call it a retro car - a statement with which Mr. Mays vehemently disagrees - it has certainly put him on the map. And it also has put California on the map as an important global design center. Tape one end of the string so that it will fit through the drilled hole more easily and tie a small knot on the other end of the string.

No comments:

Post a Comment